Empowering Complex Aquatic Projects with Design, Engineering, and Manufacturing Expertise

When it comes to commercial pool, spa, and water park projects, success depends on more than equipment supply. It requires an integrated partner who can provide systematic design, engineering execution, and professional service — from concept to completion.

With over 36 years of experience, LASWIM has become a trusted one-stop solution provider for water treatment and pool engineering projects across the world.

Comprehensive Capabilities in Design & Construction

LASWIM holds Grade I Professional Contracting License for Building Electromechanical Installation and Grade A Design & Manufacturing License for Water Amusement Facilities, Spa Systems, and Swimming Pools.

Our engineering team is capable of handling complex water circulation, filtration, heating, and automation systems for large-scale facilities such as:

-

Commercial swimming pools

-

Hotel and resort pools

-

Water parks and spa centers

-

Olympic and competition venues

We don’t just deliver equipment — we deliver turnkey solutions that combine intelligent design, energy-efficient systems, and sustainable operation.

Laswim commerical pool project

Strong R&D and Manufacturing Strength

LASWIM is recognized as a High-tech Enterprise and Specialized, Refined, Differential, and Innovative (SRDI) enterprise.

With an in-house R&D center and automated production lines, we ensure every product — from precoat micron filtration systems to high-efficiency heat pumps — meets international standards such as CE, TUV, KETI, and ROHS.

Our technology-driven innovation ensures stability, safety, and long-term efficiency for every project.

Proven Engineering Track Record

LASWIM has supplied main equipment for multiple international sports events, including:

-

The Youth Olympic Games

-

World University Games

-

Asian Youth Olympic Festival

We are also contributors to over 10 national industry standards, representing the highest engineering and quality standards in China’s aquatic industry.

Our projects have been honored with:

-

China Construction Engineering Luban Award (Top Quality Project)

-

China National Quality Engineering Award

-

Huaxia Construction Science & Technology Award

Global Service Network

With projects in more than 60 countries, LASWIM provides localized design support, technical guidance, and after-sales service to ensure every system runs smoothly and efficiently — wherever your project is.

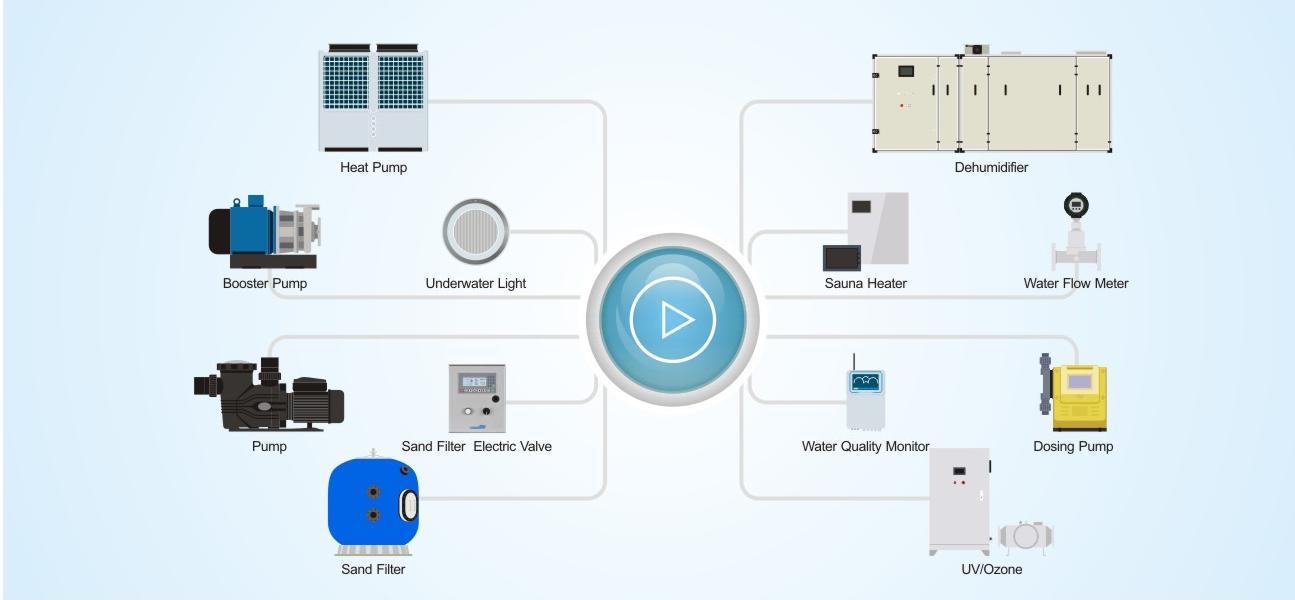

Our one-stop solution integrates:

-

System design consulting

-

Equipment manufacturing

-

On-site installation & commissioning

-

Technical training & maintenance

Why Choose LASWIM

-

Decades of experience in complex commercial aquatic systems

-

Certified engineering qualifications for design and construction

-

In-house manufacturing for all major pool and water treatment equipment

-

Proven global project performance and technical reliability

Whether it’s a five-star hotel pool, a water park, or a large public swimming complex, LASWIM delivers excellence in every drop.

Get in Touch

Looking for a reliable partner for your next commercial pool or water treatment project?

👉 Contact LASWIM today for customized engineering solutions that turn your vision into reality.